How to make custom patches with Sublimation?

Whether you're just curious, want to make your own, need to stock up on patches for a tour, or require a batch for your club or business.

This Blog will give you an idea of how it is done.

We'll give you some hints and tips on how they are made, you can also purchase blank patches if you want to sublimate patches yourself or even embroider onto them. (leave a note during checkout to send them as blank patches)

It's not an exhaustive list, and making them comes with purchasing the right equipment and lots of trial and error, hopefully, we can help you along the way with this blog.

What Is Sublimation and Why Use It for Custom Patches?

Sublimation is a printing technique that transfers a specialist ink directly into polyester fabric or a coating on a substrate using heat and pressure. The result is a long lasting design that won’t crack, peel, or fade.

Sublimation is ideal for custom patches. It allows you to produce full colour graphics with precise details, making it perfect for band logos, artwork, club emblems, or business branding.

Benefits of using Sublimation patches for your Band, Club, or Businesses.

Sublimation offers multiple advantages over traditional embroidery or screen printing:

-

Vibrant Colours: Full colour, photo quality designs

-

Durability: No cracking or peeling, even after washing

-

Fast Turnaround: Ideal for small batch or rush jobs

-

Customisation: Personalise designs with names, dates, logos, artwork and more

-

Low Minimums: Perfect for indie bands or niche businesses

Shapes and Sizes of Our Custom Sew On Patches

We offer a range of patch shapes and sizes to suit different design needs:

-

Back Patches – 23 x 30 cm (great for jackets)

-

Circular Patches – 8, 10, 20, 30 cm

-

Rectangular Patches – 10x5, 12x6 cm

-

Square Patches – 8x8, 10x10, 12x12 cm

These sizes are ideal for logos, artwork, badges, or promotional designs. All patches are sew on for added durability and easy application.

Tools and Equipment Needed to Make a Custom Patch

To create professional quality patches using sublimation, you’ll need:

-

A sublimation Printer – for small or large format printing, this can be done on printers ranging from A4 up to large scale professional printers. Such as Epson sublimation printers.

-

Sublimation Ink & Sublimation Paper produces vibrant, lasting colour – we recommend The Ink Experts for sublimation supplies

-

A Heat Press – for accurate temperature and pressure. Find out more about the best heat presses of 2025

-

Patches – Find our patches from our patches collection page

-

Heat resistant tape and cutting tools - You can find these on specialist sites like xpres.co.uk

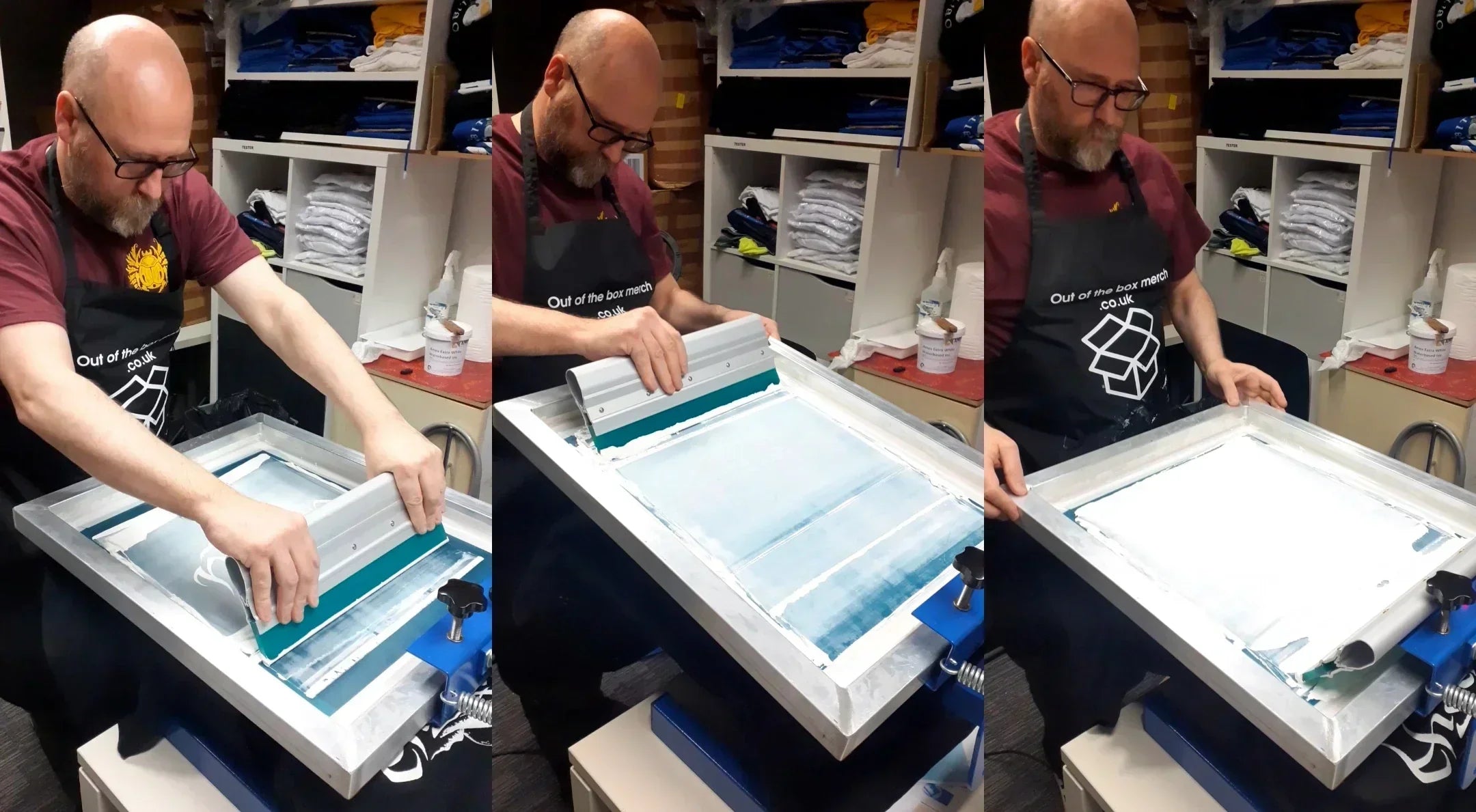

How to make your custom patches

- Design or have artwork designed for you. (Make sure the artwork is the correct size and is 300dpi)

- Print the artwork with your sublimation printer, ink and paper

- Line up and place your patches on the image or artwork

- Tape the patch into place with your heat tape so you can lift and place it onto the heat press

- Place a sheet of butcher paper on the bottom platen of the press to stop any excess ink from gassing onto the platen, and also cover the top with a Teflon sheet to protect the paper and patches as well as the top platen

- Press the patch with the correct time, temperature and pressure

- Once the press finishes the countdown, lift the press handle up and either let the patches cool down on the platen or very carefully remove them from the heat press and let them cool down in a dedicated area.

- Check the patches and make sure you're happy with the finished results.

Tips for Making Your Own Sublimation Patches

-

Always mirror (in most cases) your artwork before printing*

-

Pre-press the fabric to remove any moisture*

-

Use medium to firm pressure and the correct time and temperature (around about 90 Seconds at 200°C)*

-

Don’t rush, allow patches to cool fully before handling*

-

Test on smaller patches before moving to larger prints*

- Smaller patches lose some details, big, bold designs work best on patches

- Check out this great guide on WikiHow about sublimation

*All tips are for guidance only.

Is buying sublimation equipment right for you to make custom patches?

Okay, so not everyone will be wondering how to make custom patches with sublimation or will be able to afford all of the equipment to do so; most people won't even have the time to make their own or indeed want to.

They only need merch, and that is where we, Out of the box merch comes in.

So whether you’re a band needing back patches, a club wanting uniform badges or a brand looking to elevate your merch, we have you covered!

Out of the box merch can use our specialist knowledge and equipment and take on the job of making your custom patches for you.

We take great pride and care in making all our merchandise.

Our sublimated patches are of the highest quality, with a quick turnaround and are made to order with our tiered pricing for large volume orders.

Place an order with us today by finding your patches below.

Share:

How We Make Our Custom Slipmats for Turntables: 5 Simple Steps with images